Gren Klaipėda advances Waste-to-Energy operations with innovative Digital Twin solution

Gren Klaipėda has successfully implemented a Digital Twin solution, DWEEN, developed by Energy Advice. This innovative technology enables a mathematical model of the waste-to-energy plant, allowing advanced data analysis, process optimization, and real-time decision-making.

One of the key advantages of the Digital Twin is its ability to integrate data from various sources, including different operational systems and even external web-based data. This comprehensive approach allows Gren to simulate different scenarios, optimize plant performance, and react swiftly to market fluctuations.

Market conditions in Lithuania necessitated a reduction in boiler load to minimize electricity generation during periods of negative electricity prices. Thanks to the Digital Twin, Gren could analyze, predict, and implement this strategic adjustment efficiently, ensuring both reliable energy production and maximizing financial returns while maintaining its core mission—sustainable waste management. As Rokas Labokas, Gren Klaipėda Operation Manager, explains, “Following the implementation of the Digital Twin system, we gained access to granular operational and financial insights, not just on a monthly basis, but hourly. This enhanced visibility enables us to evaluate how different production patterns align with market conditions in real-time.”

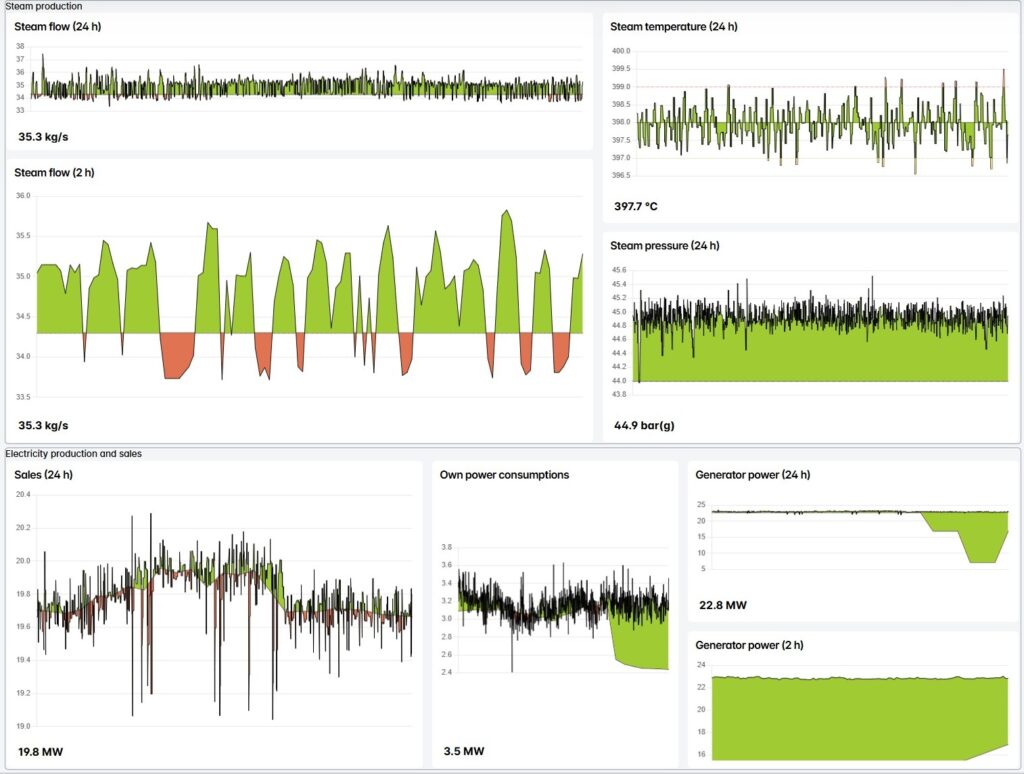

The image on the right is a screenshot showing our Digital Twin in action, operating in real-time to support enhanced monitoring and optimization.

This implementation demonstrates that Digital Twin technology is not only a powerful analytical tool but also a critical asset for optimizing energy production and enhancing financial outcomes. Importantly, waste treatment remains unaffected, ensuring environmental responsibility and sustainable operations.

By embracing digital innovation, Gren Klaipėda is setting a new benchmark in the waste-to-energy sector, showcasing how technology can drive both economic and environmental efficiency.

This project has been shortlisted for the CEWEP Technological Innovation award.